Scientific partners involved:

The LeCAD laboratory (University of Ljubljana) manages one of the few supercomputers in Slovenia, which it uses for engineering tasks. This has enabled LeCAD to enter several major international science and infrastructure programs related to supercomputing and the development of new high-performance scientific codes for simulations of complex physical processes, mostly related to nuclear fusion technology.

Codes involved:

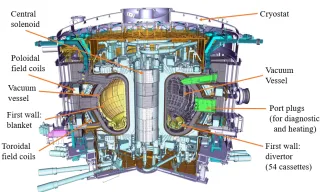

L2G, OpenFOAM and Raysect: Engineering Design and Digital Twin of the First Wall of a Tokamak Fusion Reactor

Readiness of the work:

Mid 2025

Technical Challenge:

One of the key challenges in designing the “first wall” of a tokamak fusion reactor (the component directly exposed to the extremely hot plasma inside) is accurately capturing complex physical phenomena, one of them being intense heat flux deposition to the wall. The plasma effects are especially difficult to model due to extreme heat gradients and high energy particle interactions with the wall. These make physical experiments costly and technically demanding. Moreover, the complex geometry of the wall, designed with the goal of reducing the heat flux, adds difficulty to simulations. In preparation of digital twin of the first wall of a tokamak fusion reactor, one of the challenges is to address these physical phenomena (e.g. heat flux deposition, photonic movement, and heat transfer) with sufficient complexity to arrive at a digital solution that is comparable to an actual experiment using an IR camera . This complexity comes at the cost of time and memory heavy computation.

Solution:

The three codes (L2G, OpenFOAM and Raysect) have been connected by the UL team in an initial proof-of-concept workflow to calculate a synthetic camera signal as digital twin Heat fluxes and temperatures were calculated for the full wall of the tokamak fusion reactor, taking into account the magnetic fields of the external coils and the plasma itself, heat flux of particles moving along field lines, and resulting heat transfer, to finally compute the optical effects due to the resulting radiation from the wall.

EXCELLERAT is now transforming the workflow by integrating the HPC framework that enables execution of all three simulation steps in parallel without the need for user intervention. The project is implementing automated data management systems and optimizing code for exascale computing, focusing on the parallel processing for field line tracing and thermal modeling.

Scientific impact:

The integration of field line tracing, thermal and optical simulations into a digital workflow advances the analysis of reactor components and reduces computational overhead through an integrated and parallel execution. This enables to run predictive simulations that would otherwise be too time-consuming. The capability to predict heat flux distribution permits to identify the heat loads on the wall early on, which can extend the lifetime of the wall and reduce maintenance costs. The workflow for synthetic infrared camera imaging is also crucial for real-time monitoring applications of fusion reactors. Thus, this work also brings economic and societal benefits by improving the safety of the nuclear fusion reactors.

Benefits:

- Integration of field line, thermal, and optical simulations enables reactor monitoring

- Reduction in computational overhead through automated workflow

- Capability for accurate temperature detection despite surface reflections

- Identification of hotspots before component damage occurs

Success story Highlights:

Keywords: connecting codes, digital twins

Technology: HPC

Sectors: Automotive, Energy

Contact:

Matic Brank, University of Ljubljana, LECAD, Matic.Brank@fs.uni-lj.si